Each is an example of the highest quality in design, casting, machining and finishing, crafted to the most demanding specifications, which can be repeated time after time. To meet your needs.

To service, responsiveness, solving problems, creating opportunities and achieving excellence for our partners that’s unmatched in the industry.

As one of the largest US suppliers of permanent mold castings to the power sports industry, we supply the cylinder heads, transmission cases and structural frame castings that help keep America’s premier motorcycle brand rolling down the highway. Our success is driven by our ability to make complex-cored, pressure-tight castings with superior cosmetic finishes.

ATEK Metal Technologies delivers tight tolerance, durable aluminum castings that meet the demands of aerospace, defense, trucking and automotive OEMs. Our high strength casting products reduce weight, leading to more efficient and higher performing vehicles.

You don’t have to sacrifice quality in the race to get new, lighter products to market faster. We can concept, prototype and deliver strong, high-density aluminum castings in months, for products ranging from high-end structural server components to agricultural combines and food service equipment.

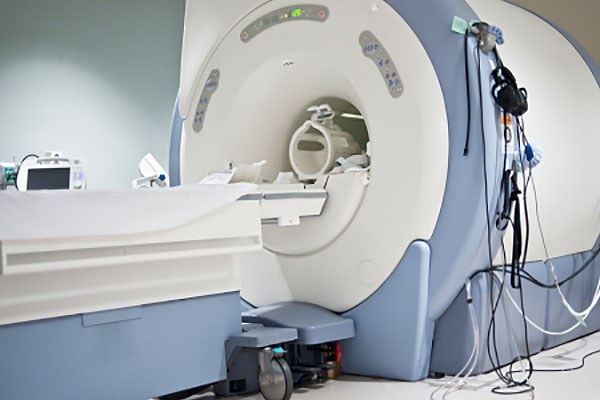

ATEK Metal Technologies’ high strength aluminum components meet the demands of complex medical OEMs, including MRI and CAT manufacturers. We do it all, from concepts and prototypes to finishing, assembly and x-raying each casting product for quality control.

AFS shares a video about Careers in Metal Casting. “The Future of Careers in Metalcasting” features interviews with young metalcasting professionals – engineers, shop floor employees, salespeople, and more. These interviewees explain why they think metalcasting is the right career choice.