ATEK Metal Technologies engineers will take time to understand your goals and work to get your products to market faster. Our optimal product design and process controls ensure you receive highly reliable, premium castings, time after time.

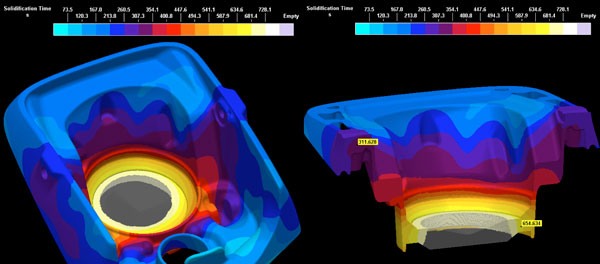

We use EKK software to run casting simulations on all new projects to verify the design and ensure accurate molds prior to tool build.

We design and build some of the industry’s most complex permanent mold tools. Once a casting CAD model is created, we’ll design and manufacture the mold and core boxes within your specified timeframe.

We perform CMM dimensional inspection and digital scanning to verify the casting geometry meets your required tolerance. Digital scanning of the casting, tooling and cores (when applicable) allows data comparison to the CAD model and locates any precise dimensional deviation.

All new projects follow a rigorous APQP (Advanced Product Quality Planning) development process to ensure program success. Additionally, we perform a detailed PPAP (Production Part Approval Process) to adhere to your requirements or in accordance with current AIAG standards.